巴特利特建筑学院研究员用新软件设计制作Voxel椅子

Robot-made Voxel chair designed using new software by Bartlett researchers

由专筑网李韧,韩平编译

这种机器制造椅子由一种连续的塑料制成,是由伦敦巴特利特建筑学院用3D打印设备设计制作。

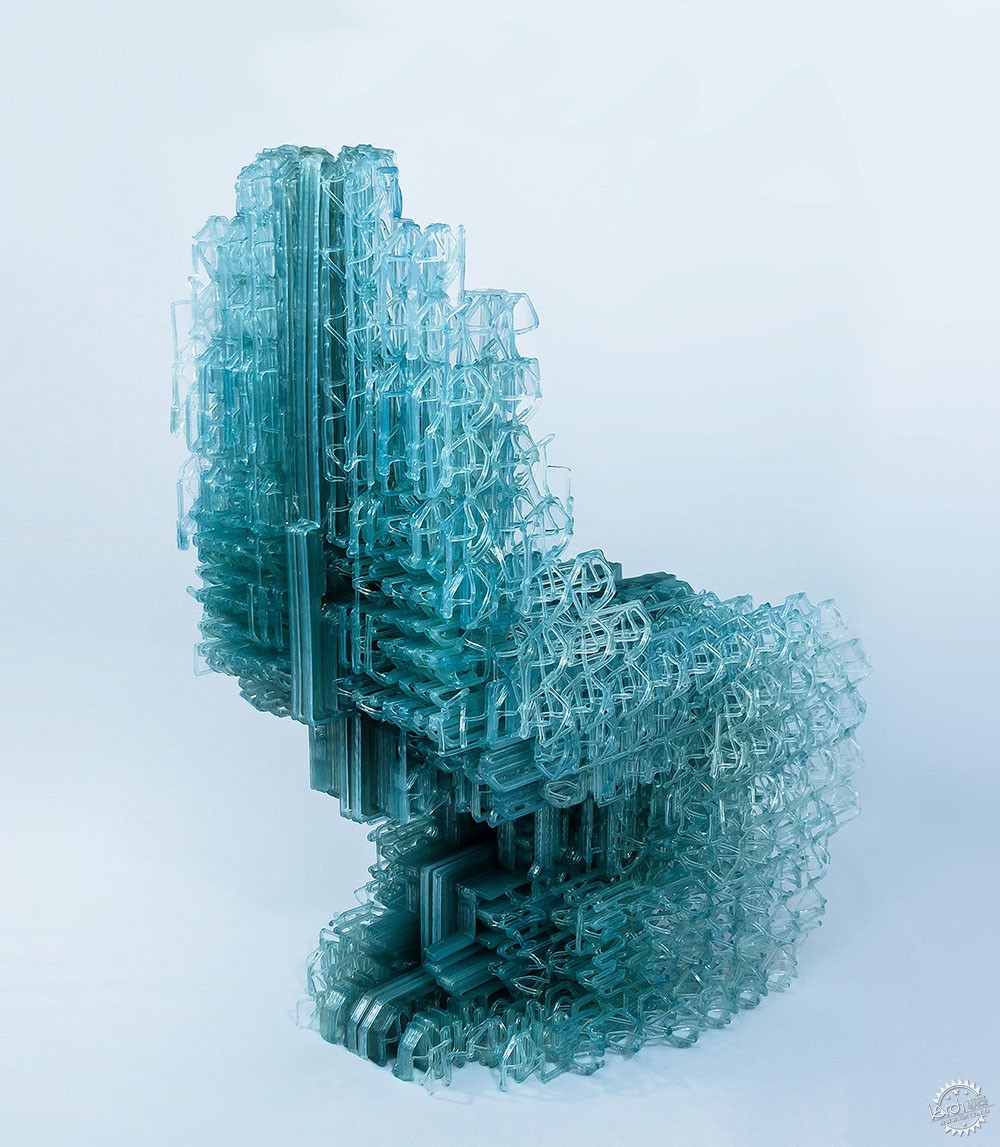

A continuous line of plastic makes up this intricate robot-built chair, designed using a new 3D-printing software by a team from the Bartlett School of Architecture in London.

巴特利特设计计算实验室(DCL)是伦敦大学的重要组成部分,这个实验室实现了3D打印的更多可能性。

而当前最新的3D打印技术主要采用创建图层的方式,DCL使用的软件则运用的是一种连续不断的材料。设计思路是通过一个机器设备,将塑料熔融并加入空气,这样塑料很快就遇冷凝固。

该软件具有很多好处,例如这样能够创造更复杂的模式,让设计师能够创造更便捷高效的产品形式。

The Bartlett's Design Computation Lab (DCL), a part of University College London, created the software to open up new possibilities for 3D printing.

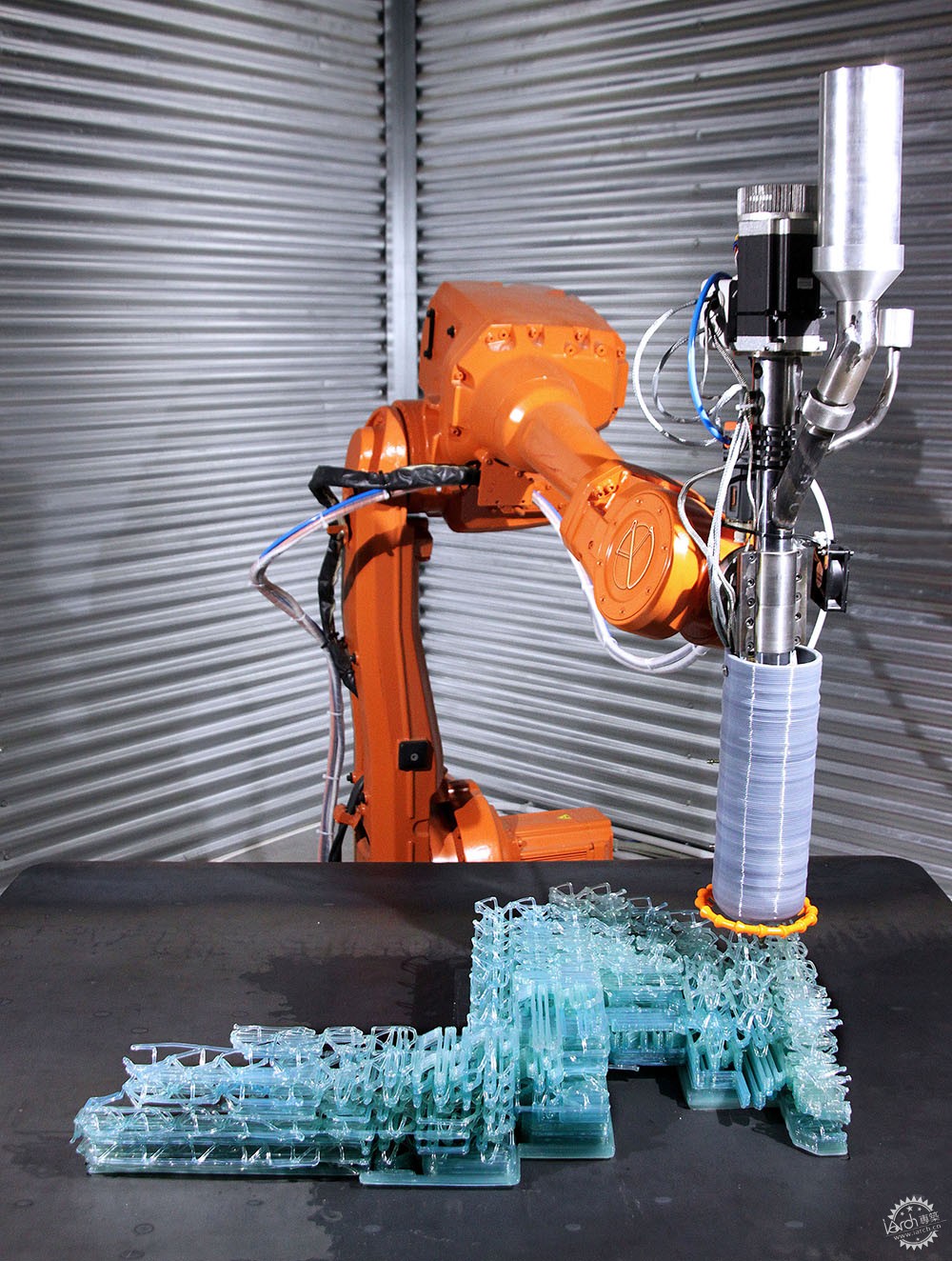

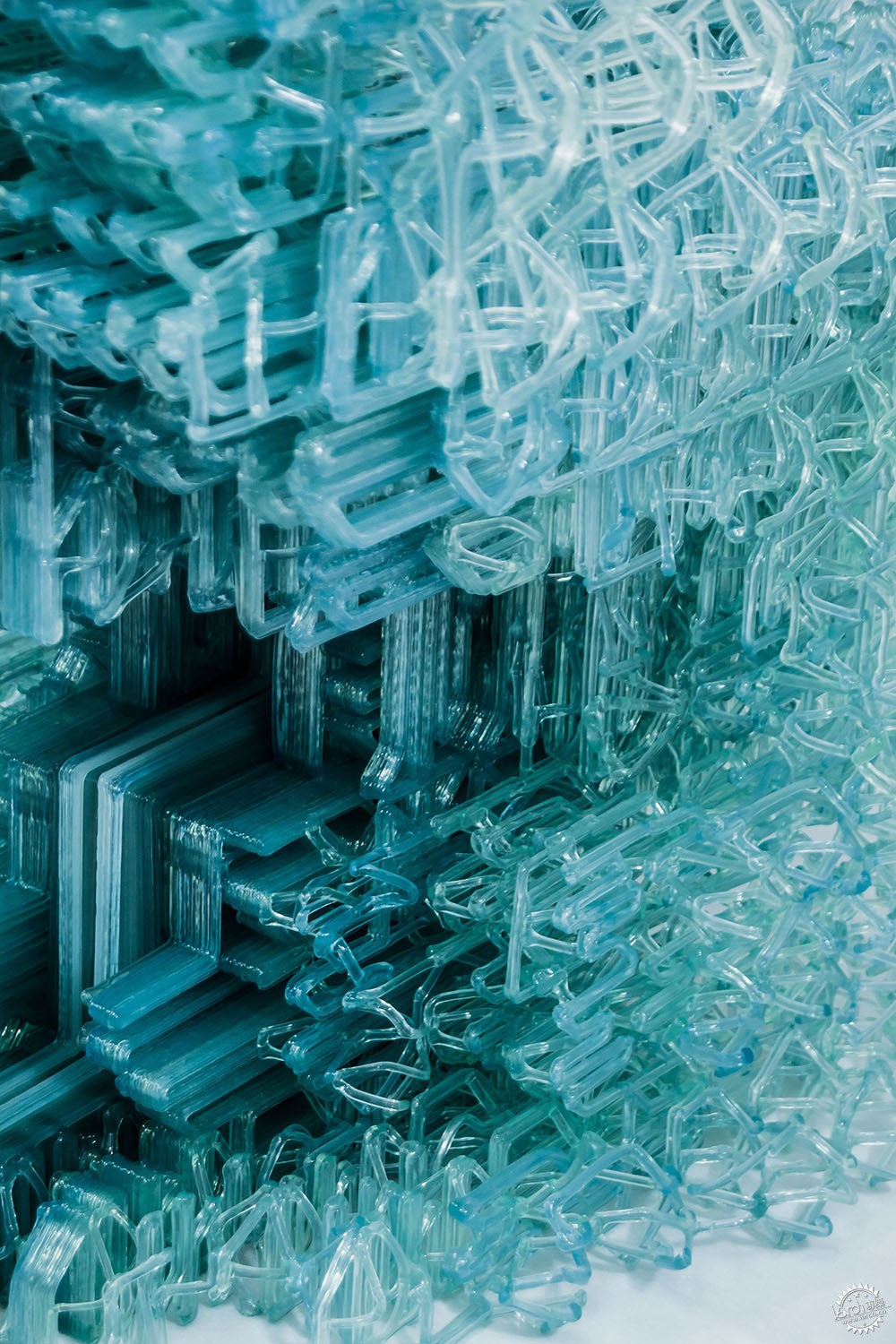

Whereas most current 3D printing involves creating forms layer by layer, DCL's software creates designs using one continuous line of material. The designs are then built by a robot that extrudes melted plastic into the air, where it quickly sets as it cools.

As well as enabling the creation of more intricate patterns, the software has a functional benefit, allowing designers to create lighter, more efficient forms without using any more material than is necessary for load bearing.

这种软件可以用于大型结构的设计,这些结构的内部极其复杂,如Hasso Plattner学院的塑料门插销。

“这种方法的功能很全面,但同时它也为设计人员提供了令人难以置信的准确数据。”DCL的联合董事Manuel Jiménez Garcia和Gilles Retsin表示。

“相比起直接设计椅子的形式,这种设计方式直接表达了材料的性质与品质。”

设计小组创建了一个塑料椅子原型。由透明、可降解的聚乳酸塑料制成,椅子原型是丹麦设计师Verner Panton设计的 “S”形Panton椅。

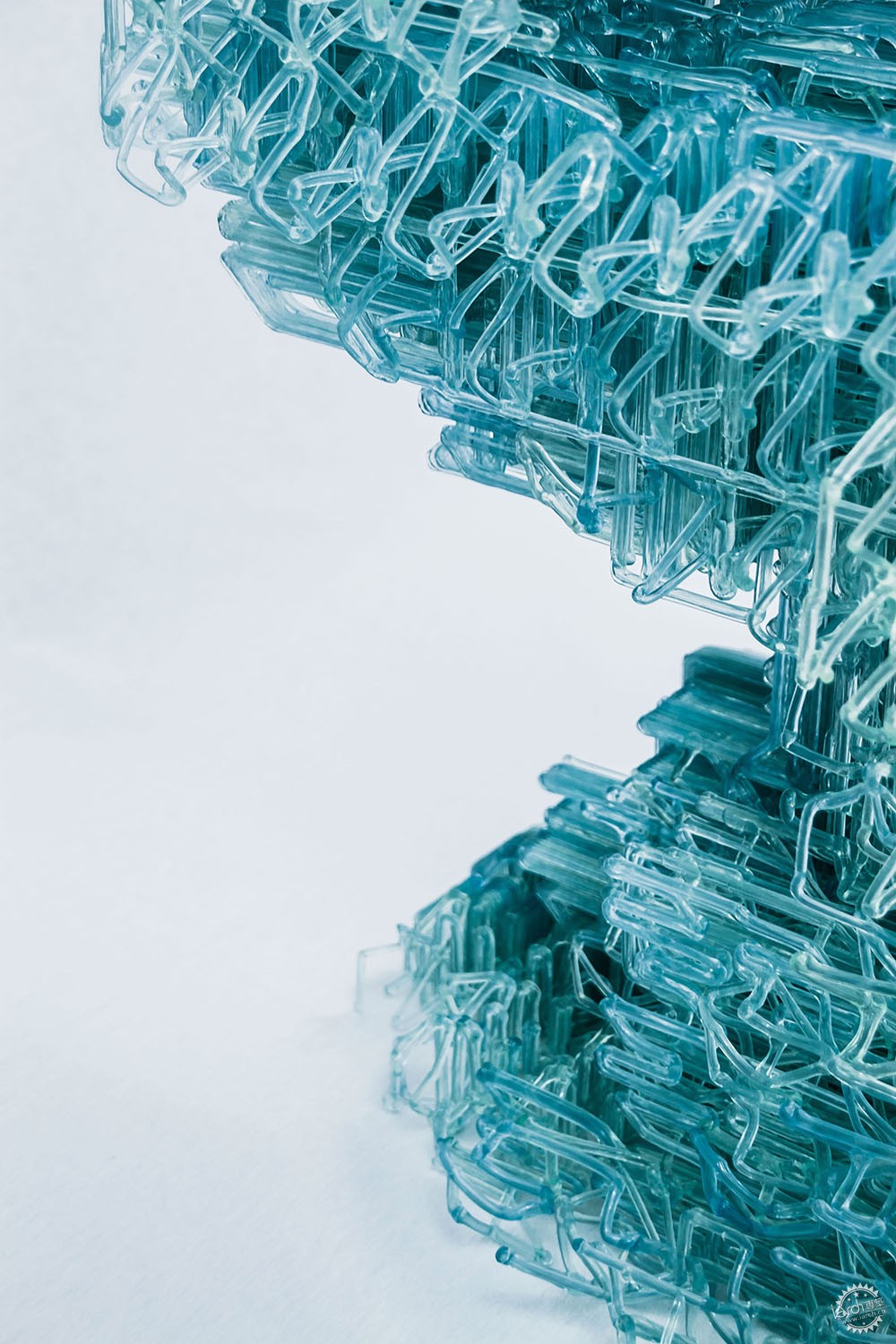

DCL实验室采用这种椅子的原型是因为其具有很高的辨识度,椅子整体是一个充满“挑战”的悬臂结构。但原先的椅子运用的是固体胶,DCL实验室则运用了一个复杂的网络从而通过机器制造连续2.36公里的塑料而创造出来。

“这可能看起来像Panton椅,但实际上完全不同。”设计师说,“Panton椅是用优化模具制作而成的纯粹表面。而这把椅子则相反,它具有云朵般的体量,并且通过机器优化设计。

It can also be used for the design of large-scale metamaterials, which have an internal structure engineered for certain behaviours, like Hasso Plattner Institute's all-plastic door latch.

"This approach is not only more functional in terms of performance, but it also offers designers opportunities to really work directly with incredible amounts of data," said DCL's co-directors Manuel Jiménez Garcia and Gilles Retsin.

"Instead of designing the form of the chair, you design the behaviours and properties of the material directly."

The team tested the software by creating a prototype piece of furniture, the Voxel Chair v1.0. Made from transparent, biodegradable PLA plastic with a blue tint, the chair is modelled on the iconic S-shaped Panton chair by Danish designer Verner Panton.

DCL likes working with this chair shape because as well as being instantly recognisable, it has a "challenging" cantilever geometry. But where the original chair is solid plastic, DCL's is a complex web of hollows created by a robot extruding plastic in one continuous 2.36-kilometre line.

"This may look like a Panton chair, but it's actually completely different," said the designers. "The Panton chair was a pure surface, optimised to mould. This chair is the opposite: a cloud-like volume, optimised for robotic extrusion."

CurVoxels团队看到这样一个类似手工作品的椅子之后,他们试图通过设计一个软件产品从而“概括”这种设计方法,这样人们便能够生产出不同版本的椅子,并使他人能够复制同样的过程。

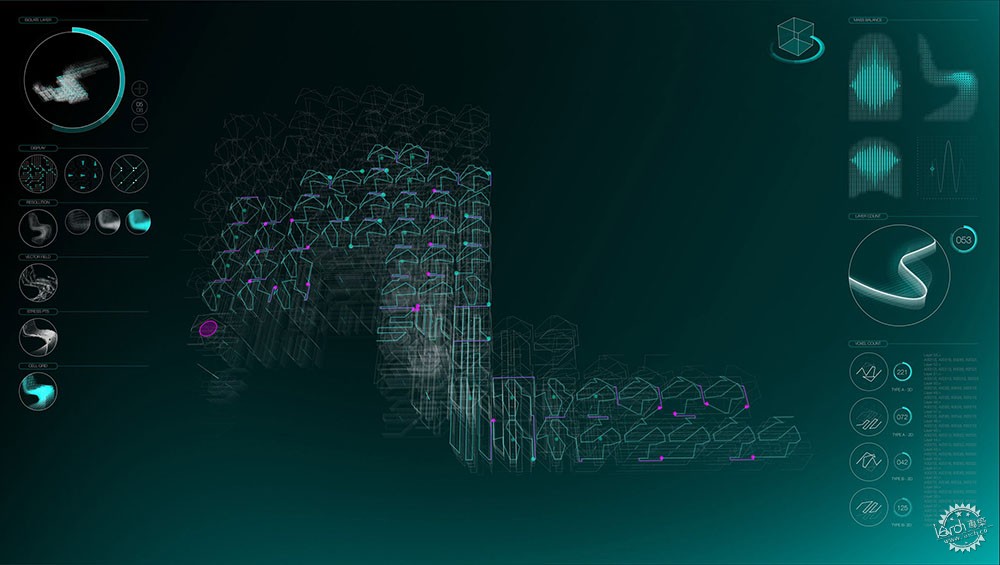

该软件旨在给设计师更便于控制的3D打印过程。而他们通常会使用软件来模拟一个对象,然后通过各种方法进行制作,再结合DCL实验室的发明,人们便可以直接操纵制作路径。

A previous project by the team, CurVoxels, saw them create a similar filigreed Panton-like chair as a one-off. After that project, they sought to "generalise" this design approach by creating software that would enable them to test out different versions of the chair, and to enable others to replicate the same process.

The software is intended to give designers greater control over the 3D-printing process. Whereas they would usually use software to model an object that would then be automatically "sliced" into layers – or tool paths – for printing, with DCL's invention, they can manipulate the tool paths directly.

“作为设计师,我们通常不能控制或使用这些工具路径的设计过程。”Jiménez Garcia和Retsin说。

“我们的软件允许设计师绕过这一缺点,自行操作设计工具路径,这样我们就能够控制更多的细节。”

椅子被命名为Voxels,它的作用像三维空间的像素,并经常用于医学图像和视频游戏。DCL实验室的软件基于Voxels从而允许用户自行设计物体的内部,使设计并不仅仅局限于表面。

该小组还开发了一个新的机器用于在该项目中,这个机器能够直接熔融塑料颗粒,从而不需要使用长丝。设计师说,这有助于降低成本,这种工艺可用于更大规模的工业设计。

该软件目前仍处于开发阶段。它获得2016年Autodesk公司的ACADIA新兴研究奖的优秀论文称号,并将在2017年11月在麻省理工学院(MIT)举办的ACADIA会议上颁奖。

"As designers we can't usually control these or use these tool paths themselves as a medium to design with – its a very top-down process," said Jiménez Garcia and Retsin.

"Our software allows designers to bypass this, and immediately design with the tool paths themselves – which gives you access to much more detail and control."

The chair is named after voxels, which act like pixels but in three-dimensional space, and are often used in medical imaging and video games. DCL's software is based on voxels to allow users to design the insides of an object and not just its surface.

The team also developed a new extruder for the robot used in the project, which directly melts raw plastic pellets rather than using filament. The designers said this helps reduce cost and make the process viable on an industrial scale.

The software is currently still in development. It received the 2016 Autodesk ACADIA Emerging Research Award for best paper and will be presented at the 2017 ACADIA conference at the Massachusetts Institute of Technology (MIT) in November.

项目信息:

设计:Gilles Retsin, Manuel Jiménez Garcia

团队:Manuel Jimenez Garcia, Miguel Angel Jimenez Garcia, Ignacio Viguera Ochoa, Gilles Retsin, Vicente Soler

制造支持:Nagami Design, Vicente Soler

Project credits:

Design: Gilles Retsin and Manuel Jiménez Garcia

Team: Manuel Jimenez Garcia, Miguel Angel Jimenez Garcia, Ignacio Viguera Ochoa, Gilles Retsin, Vicente Soler

Fabrication support: Nagami Design, Vicente Soler

出处:本文译自www.dezeen.com/,转载请注明出处。

|

|