Five ways architects and designers are helping the fight against coronavirus

由专筑网小R编译

从设计面罩到扁平化重症监护病房,再到3D打印无接触门杆和改造医院,建筑师和设计师们针对新冠病毒进行了多种构思,如下为5种设计策略。

From designing face shields and flat-pack intensive care units to 3D-printing hands-free door levers and converting buildings to hospitals, architects and designers are tackling the coronavirus pandemic. Here are five ways they are helping.

改造医院

新冠病毒感染患者数量空前巨大,因此各个国家都不得不提升病人收治容量。

那么为了做到这一点,全球的建筑都在将各个不同的建筑改造为重症病房。例如在德黑兰的伊朗购物中心,也是全球最大的购物中心,这里就被改造为新冠病毒医院,同时纽约的圣约翰大教堂也进行了改造。

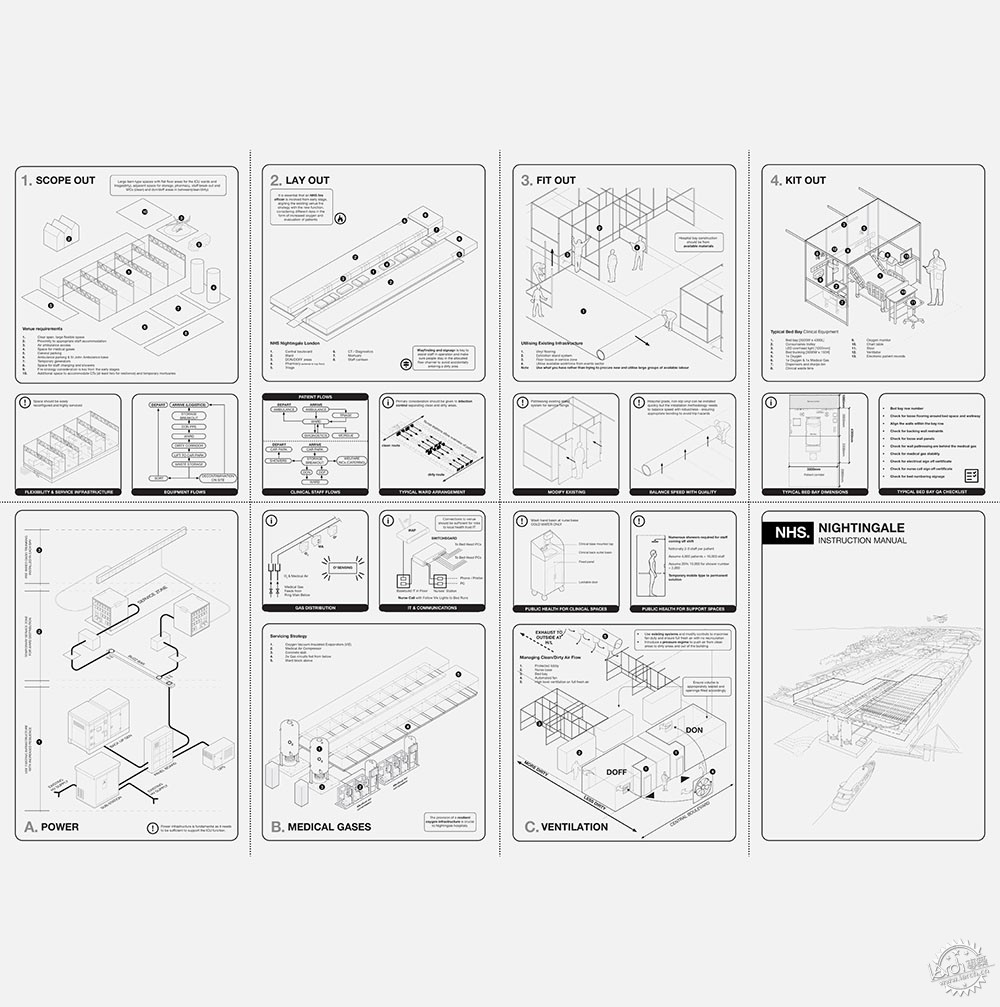

会议中心有着大量的开放空间,也是一个很好的改造地点,BDP建筑工作室将英国伦敦的ExCel中心改造为4000床的NHS Nightingale医院。

建筑里设计有两个大型病房,依据不同的区域和中央走廊分隔开,便于医护人员穿脱防护服,另外还有员工食堂、诊疗室,以及停尸房。

James Hepburn说:“伦敦的床位十分短缺,而ExCel中心则是很好的选择。”

“这里有着很大的楼层空间和灵活的MEP设施,因此很满足临时医院的需求。”

Converting buildings to hospitals

The unprecedented number of coronavirus cases is forcing countries around the world to rapidly increase their capacity to treat patients.

To do this, buildings across the world are being converted into intensive care units. In Tehran, Iran Mall, the world's largest shopping centre, is being transformed into a coronavirus hospital, while in New York the Cathedral of St. John the Divine is also set to be converted.

With large open spaces, conference centres are an obvious choice for conversion and architecture studio BDP has converted the ExCel Centre in London into a 4,000-bed hospital called NHS Nightingale.

Two giant wards have been created in the exhibition halls, which are divide from a central corridor by areas to put on and take off protective clothing. A staff canteen, diagnosis room and mortuary complete the hospital.

"When the scale of the shortfall in beds across London became clear, the ExCel centre was the obvious choice," BDP's James Hepburn told Dezeen.

"It has huge flat floor hall spaces with flexible MEP infrastructure that can be easily adapted to meet the needs of the temporary hospital."

临时重症监护室

建筑师们意识到需要建立临时的重症监护室,在疾病大面积爆发后收治病人。

为了应对美国的疫情爆发,扁平化新兴企业Jupe设计了一系列的医疗设施,目的是快速地安装医疗设备,增加医院收治容量,同时也可以用于独立的野战医院。

Jupe首席医疗顾问Esther Choo解释:“当联邦政府的救援计划开始实施时,医院也无法迅速地解决所有问题。”

在意大利,建筑师Carlo Ratti和Italo Rota用集装箱设计了重症监护舱,其首个原型应用在米兰的一座医院中。

Designing temporary intensive care units

Architects have also recognised the need to create temporary intensive care units that can be rapidly deployed, following China's rapid construction of a temporary hospital to treat patients at the start of the pandemic.

In response to the outbreak in the USA, flat-pack startup Jupe has created a range of medical care facilities that are designed to be quickly installed at hospitals to increase bed capacity, or that could be used as stand-alone field hospitals.

"Hospitals can't tackle it all rapidly enough, even once the federal government's aid package kicks in," explained Jupe chief medical advisor Esther Choo.

In Italy, architects Carlo Ratti and Italo Rota designed an intensive-care pod within a shipping container. The first prototype is currently under construction at a hospital in Milan.

设计面罩

许多国家的医护人员防护设备十分紧缺,因此建筑师和设计师已经着手开始设计与制造。

美国诸如BIG、KPF、Handel建筑事务所已经加入了一个开放项目,目的是打印防护面罩,同时西班牙的3D打印品牌Nagami Design也已经将机器改造用于制作面罩。

英国福斯特建筑事务所决定设计一种激光切割替代面罩,这种开放设备能够经过消毒而重复使用。

麻省理工学院、剑桥大学、昆士兰大学,以及罗德岛设计学院的毕业生们也在积极设计面罩。

麻省理工学院设计了一种一次性面罩,这种面罩由塑料制作而成,能够批量生产,易于运输,折叠之后即可使用。

罗德岛设计学院的毕业生设计了一种简单的面罩,这种面罩是将弯曲的塑料和头巾结合在一起,而剑桥大学和昆士兰大学的学生们的设计甚至无法特殊材料和工具。

Designing face shields

In some countries, the pandemic has led to a shortage of personal protective equipment (PPE) to protect health workers. In response, architects and designers have begun designing and manufacturing it themselves.

In the USA, studios including BIG, KPF and Handel Architects have joined an open-source project to print face shields, while in Spain 3D-printing brand Nagami Design has switched its machines from making furniture to shields.

British architecture studio Foster + Partners decided to design an alternative face shield that can be laser cut. The open-source device can be disassembled and sanitised for reuse.

Researchers at the Massachusetts Institute of Technology (MIT), the University of Cambridge and the University of Queensland, and graduates from Rhode Island School of Design have all also designed face shields.

MIT has developed a disposable face shield that is made from a single piece of plastic, which can be mass-produced and shipped flat. Pieces of plastic and be folded into a three-dimensional structure when needed.

The RISD graduates created a simple shield that combines a curved piece of plastic with a headstrap, while the University of Cambridge and the University of Queensland's design can be created with no specialist materials or tools.

制作口罩

口罩是个人防护用品,在疫情期间的需求量大大增加,为了应对这种需求变化,许多设计与时尚品牌都开始生产口罩。

Prada、COS、Louis Vuitton领先开始生产外科口罩,而Yves Saint Laurent和Balenciaga则开始生产棉口罩。

Making face masks

Face masks are another item of PPE that have seen a massive increase in demand during the pandemic. In response to shortages, numerous designs and fashion brands have converted their factories to mask production.

Prada, COS and Louis Vuitton are among the leading brands that have retooled to manufacture surgical face masks, while Yves Saint Laurent and Balenciaga have begun production of cotton face masks.

抗疫黑科技

建筑师和设计师在使用3D打印工具来快速地完成项目,这些项目能够让设备用于解决由于疫情而引发的问题。

中国3D打印制造商Creality为了缓解医护人员在治疗病人是戴口罩的痛苦,设计师们设计了一种特殊设备,这种设备能够能够让口罩无需挂在耳朵上。

建筑师Ivo Tedbury和Freddie Hong设计了一种3D打印门把手延长构件,这样使用者可以无接触地开门。

在意大利,由于需求量大,制造商Isinnova通过3D打印生产了一种氧气面罩关键阀,这种设备曾经用于通风机。

Isinnova公司的CEO Cristian Fracass说:“这种关键阀有很小的孔和管,尺寸小于0.8毫米,打印难度比较大,但是必须以无污染的方式进行临床生产。”

Hacking equipment

Architects and designers have been using their 3D-printers to quickly create items that alter equipment to solve problems raised by the pandemic.

To make wearing face masks less painful for medical staff treating patients, Chinese 3D-printer manufacturer Creality is printing a device that holds the strings away from the wearer's ears.

Architectural designers Ivo Tedbury and Freddie Hong have created a 3D-printed door-handle extension that users can loop their arm through so they can open doors without using their hands.

In Italy, additive manufacturing start-up Isinnova reverse engineered and 3D-printed a crucial valve for a oxygen mask, which is used as part of a ventilator machine, following a shortage.

"The valve has very thin holes and tubes, smaller than 0.8 millimetres – it's not easy to print the pieces," said Isinnova CEO Cristian Fracass. "Plus you have to respect not [contaminating] the product – really it should be produced in a clinical way."

|

|