Carbon fibre and robots could create a "fourth industrial revolution" says expert

由专筑网Ann,刘庆新编译

建筑师兼研究员Achim Menges表示,碳纤维目前是建筑方面最具开发潜力的材料资源,他声称机器人程序可以利用纤维建筑材料建造体育场的屋顶。

Menges是斯图加特大学参数化设计研究中心的负责人,正在开发一种软件程序使器械操作更加直观,目前正在对该程序进行测试,建造一个碳化纤维的构筑物。

建筑师认为现代信息技术和物理制造业的结合,必将引起建造行业的一场深刻变革。

Carbon fibre is architecture's biggest untapped resource according to architect and researcher Achim Menges, who claims that robots could be programmed to build stadium roofs using the fibrous building material.

Menges – who heads up the Institute for Computational Design at the University of Stuttgart – is developing a software program to make robotic construction more intuitive and has been experimenting with the system to build a carbon-fibre pavilion.

The architect believes projects like this, which combine digital technology and physical fabrication, have the potential to completely revolutionise the construction industry.

Achim Menges(右)正在与建筑师Moritz Dörstelmann (左)和工程师Jan Knippers(中间)进行伦敦V&A博物馆的碳化纤维装置的设计/Achim Menges (right) is currently working with architect Moritz Dörstelmann (left) and engineer Jan Knippers (middle) on a carbon-fibre pavilion for London's V&A

在Dezeen的最近一次访问中,Menges表示:“它现在仍属于一种新的技术,还没有被完全开发及商业化。”

“我们不仅仅关注事物被制造出来的发展历程,它是非常令人惊异的转变,从某种程度上说,像第四次工业革命一样。”

Menges相信碳纤维的可能性尚未被完全发掘,而机器制造业能够加速它的开发过程。

“材料的内在性能还没有被充分利用,我们还没有脱离新材料模仿旧材料的建造方式的阶段。”

"It's a very new technology so nobody has picked it up and commercialised it," he told Dezeen during a recent visit to the school.

"We're not just looking at a gradual evolution of how things are made," he added. "It's a pretty dramatic shift, a kind of fourth industrial revolution."

Menges believes the full possibilities of carbon fibre in construction are still yet to be revealed, and claims that robotic fabrication could help unlock its potential.

"The genuine possibilities inherent in the material are not fully tapped into," he said. "We haven't left that phase where these new materials are mimicking old materials."

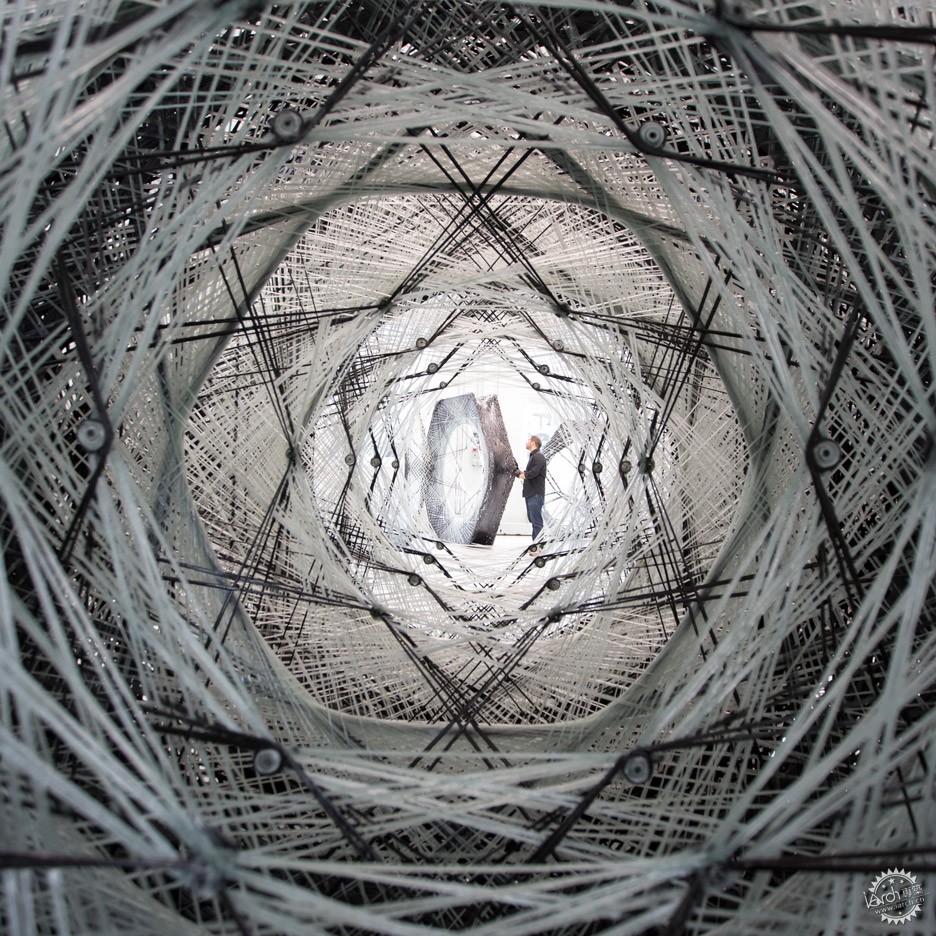

Menges表示机器制造业有助于碳纤维材料的开发/Menges claims that robotic fabrication could help unlock the potential of carbon fibre

在过去几年中,Menges一直与工程师Jan Knippers探索自然界中的何种结构能够对未来建筑有所启示,目前,另一名工程师Thomas Auer和建筑师Moritz Dörstelmann也加入了他们的研究队伍,共同致力于伦敦V&A博物馆的碳纤维亭的建造项目中。

他们已经开发的其中一项技术是机械纺织,将碳纤维材料直接裸露在外,而不是将其嵌入基质材料中——他们相信将有可能使碳纤维结构庞大而坚固,足以形成体育场的屋顶。

Menges表示:“这种技术有可能应用在未来的建筑中。”

他表示,主要的障碍是设备程序的进展需要器械制造的调控。

Menges has spent the last few years working with engineer Jan Knippers exploring whether structures found in nature could set a precedent for future architecture. They are currently working with another engineer, Thomas Auer, and architect Moritz Dörstelmann on a robotically fabricated carbon-fibre pavilion for London's V&A museum.

One of the techniques they have developed is a form of robotic weaving that leaves fibres exposed rather than embedding them in a host material – a system they believe could make it possible to build carbon-fibre structures large and strong enough to form roofs for stadiums.

"This could find an application in architecture tomorrow," said Menges.

The primary hurdle, he said, is the development of the computer software needed to control the robotic construction.

一对库卡机器人被应用到V&A装置的建造中/A pair of KUKA robots have been used to build a prototype for the V&A pavilion

碳纤维是一种纤维增强复合材料,它与纤维水泥和玻璃纤维一起,是建筑中最新、最具革命性的材料之一。

该材料最初在20世纪60年代崭露头角,高性能的抗张强度使其成为设备和运输行业的理想选择。碳纤维在近几年被广泛使用,第一批大规模生产碳纤维汽车和飞机——宝马i3和波音787梦想飞机––最近已经面世。

在更多的时候,碳纤维用于铸模,模仿传统材料的应用方法。但将新型材料应用在旧的技术手段上,就失去了探索并发挥新材料潜力的机会,Menges表示。

“不论是在设计语言还是在结构性能上,纤维材料都没有充分发挥出自身材料的固有性能和特色。”

Carbon fibre is part of a family of fibre-reinforced composites which, alongside fibre cement and glass fibre, are among the newest and most revolutionary materials in construction.

The material first rose into prominence in the 1960s, with its high tensile strength making it an ideal candidate for both the furniture and transport industries. It has become more widely used in recent years, and the first mass-produced carbon-fibre car and plane –the BMW i3 and the Boeing 787 Dreamliner – have recently been introduced.

For the most part, carbon-fibre components are formed in moulds and are designed to mimic more traditional materials. But by applying this old technique to a relatively new group of materials, the construction industry is missing out the chance to fully explore it as a fibrous material, according to Menges.

"[Fibrous materials] are still not used in a way that really explores the intrinsic material properties and characteristics," he said, "both in terms of the design language, but also in terms of the structural capacities that they have."

团队已经开发出一种编织系统,可以使碳纤维结构强大而结实,应用在体育场屋顶的建造中/The team has a developed a weaving system that could make it possible to build carbon-fibre structures large and strong enough to form roofs for stadiums

首先应用了碳纤维材料的建筑包括Snøhetta近期完成的SFMOMA扩建项目,体现出了对自动化和航空航天工业美学上的模仿。

据Menges表示,模具的使用是代价昂贵的——促进了装配生产并阻碍了进一步的探索——对于一次性建筑物的建造来说过于浪费。

汽车行业所使用的机械装置用来执行和重复相同的任务,与之不同的是,斯图加特的设计团队正在研发一个新的装置,使机械手臂更加智能,能够量身定制所需要的结构。

The first forays into carbon-fibre architecture, including Snøhetta's recently completed extension to SFMOMA, are copy-catting the high-gloss aesthetics of the automotive and aerospace industries, he said.

According to Menges, the use of moulds is both prohibitively expensive – encouraging serial production and stifling further experimentation – and wasteful for the production of one-off buildings.

Unlike the robots used by the car industry, which are taught to carry out and repeat one task, the team in Stuttgart is developing software to make each movement of the robotic arm more intelligent, resulting in tailor-made structures.

一节节的碳和玻璃纤维从机器中通过,并涂抹上树脂材料,然后缠绕上金属支架/Lengths of carbon and glass fibre are drawn through a resin bath by the robot, and then wound around metal scaffolding

Menges 和 Knippers在研究中已经探索了许多材料的可能性,他们也曾受到生物结构的启发,比如海胆的壳状结构和甲壳虫的翅膀。

他们与学生一起利用参数化设计、仿生和制造业的研究成果,其中一部分在学校的年度展示中曾经阐释过。

Menges and Knippers have explored the possibilities of numerous materials as part of their ongoing material research, which is informed by biological structures like the shell of a sea urchin or the wings of the beetle.

Some of the results have been revealed through the school's annual pavilion series, which they produce with students using computational design, simulation and fabrication processes.

树脂涂层结构通过一个巨大的烤箱进行固化分离,形成独立的构件/The resin-coated structures are cured in a giant oven before being detached from their framework to form stand-alone pieces

斯图加特设计团队对伦敦V&A博物馆设计的碳化纤维装置基于早些时候对水纺蛛蛛网结构的研究。

项目被称作Elytra Filament Pavilion(翅鞘纤维亭),将作为博物馆的工程装置进行展示,目前正在由机器人在位于旧柯达工厂的仓库空间中建造。

一节节的碳和玻璃纤维从机器中通过,并涂抹上树脂材料,然后缠绕上金属支架。树脂涂层结构通过一个巨大的烤箱进行固化分离,形成独立的构件。

The Stuttgart team's carbon-fibre pavilion for the V&A courtyard in London will be based on a earlier investigation into the webs of water spiders.

Called the Elytra Filament Pavilion, it will be erected as part of the museum's engineering season and is currently being built by a robot in their warehouse space behind an old Kodak factory in the city.

Lengths of carbon and glass fibre are drawn through a resin bath by the robot, and then wound around metal scaffolding. The resin-coated structures are then cured in a giant oven before being detached from their framework to form stand-alone pieces.

斯图加特设计团队对伦敦V&A博物馆设计的碳化纤维装置基于早些时候对水纺蛛蛛网结构的研究/The Stuttgart team's carbon-fibre pavilion for the V&A courtyard in London will be based on a earlier investigation into the webs of water spiders

研发团队的其他项目包括由30000个尖尖的构件组成的艺术装置和含有超过百分之90可再生材料组成的生物塑料结构。

项目基于已故的德国建筑师和工程师弗雷•奥托(Frei Otto)的研究,Frei Otto以其杰出的拉伸膜结构闻名,他们同属于一家研究机构。

以上图片来自于斯图加特大学和V&A博物馆。

Other past projects by the team include a pavilion constructed from 30,000 spiky components and a structure made from a bioplastic containing over 90 percent renewable materials.

The work builds on the research carried out by Frei Otto, the late German architect and engineer, who was known for his pioneering development of tensile and membrane structures, and who worked at the same institute.

Images courtesy of the University of Stuttgart and the V&A.

出处:本文译自www.dezeen.com/,转载请注明出处。

|

|