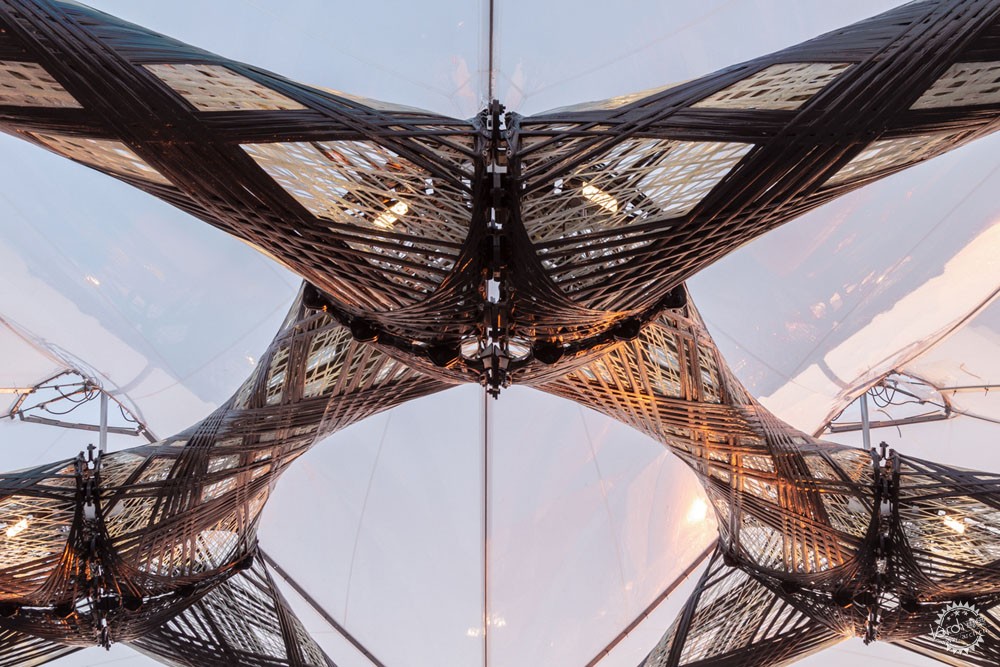

Courtesy ICD/ITKE University of Stuttgart

Is Carbon Fiber All it Cracked Up to Be?

由专筑网亚森君,李韧编译

Blaine Brownell回顾了碳纤维技术的最新应用成果,并评估了其在环保建筑方面的实用性。

为了向大众推销Dymaxion原型设计, Buckminster Fuller提出了一个著名的问题:“你的房子有多重?” Dymaxion由一根中央桅杆拉紧的轻质金属铝外壳组成,重量只有1.5吨左右,约为普通房屋重量的10%。

Fuller对重量的重视这一观点,对于今天的人们来说更加重要,因为在全球范围内,原材料与加工材料的运输对环境的影响越来越大。汽车和航空航天工业在“轻量化”战略方面取得了重大进展,它们采用了全新轻质材料以减少部件的重量。此种战略使美国航空公司燃油效率在1978年至2017年间显著提高了125%。

从一级方程式赛车车身到自行车部件,碳纤维越来越多地用于制造超轻型结构。碳纤维通常由碳丝扭结而成,再涂上树脂或热塑性塑料,从而形成强度重量比非常高的复合材料。其强度是钢的五倍,却比钢轻五倍,硬度是钢的两倍,十分耐热和抗腐蚀,是极端环境下的理想选择。

Blaine Brownell reviews recent applications of carbon fiber technology and assesses its utility in environmentally conscious construction.

To market the design for his Dymaxion prototype, Buckminster Fuller famously asked: “How much does your house weigh?” Composed of a lightweight sheet metal aluminum skin held in tension by a single, central mast, the Dymaxion weighed only about 1.5 tons—about 10 percent the weight of an average house.

Fuller's emphasis on weight is even more critical today, given the ever-increasing environmental impact of shipping raw and processed materials around the planet. The automotive and aerospace industries have made significant advances in the strategy known as "lightweighting" by employing new and lighter materials and reducing the weight of components. Such an approach enabled U.S. airlines to significantly increase fuel efficiency by 125 percent between 1978 and 2017.

Carbon fiber is increasingly employed in the fabrication of many ultralight structures, from Formula One car bodies to bicycle components. Made from carbon filaments that are typically woven together into a cloth, carbon fiber is often coated with resin or thermoplastics to create composites with a very high strength-to-weight ratio. The result is a material about five times stronger and five times lighter than steel—and twice as stiff—that can readily tolerate heat and corrosion, making it ideal for extreme environments.

Courtesy ICD/ITKE University of Stuttgart

尽管碳纤维的成本相对较高,但建筑师和工程师已经开始使用它来建造建筑物和基础设施项目。例如,斯图加特大学计算设计与施工研究所(ICD)和建筑结构与结构设计研究所(ITKE)的研究人员的最新成果,就把碳纤维用作主要的建筑材料,在德国海尔布隆Bundesgartenschau园艺博览会上展出的“2019 BUGA纤维馆”,就有着由玻璃纤维和碳纤维肋骨制成的圆顶,覆上了一层透明的ETFE膜。研究小组通过对机器人编程,使其能够根据指定的空间形态扭结超过492,000英尺的纤维丝,纤维的类型和密度可以根据结构载荷的不同而变化。为了模拟生物系统,碳纤维环绕透明的玻璃纤维形成束状结构,类似于弯曲的肌肉组织。根据研究小组的说法,单一的纤维成分可以支撑“25吨或15辆汽车的重量”。穹顶的自由跨度约为75英尺,建筑面积为4,305平方英尺,由60个这样的部件组成,每平方米仅重16.8磅。

虽然ICD / ITKE的成果采用了定制示范的形式,但另一个研究团队已经在公共基础设施中广泛应用了碳纤维。缅因大学高级结构与复合材料中心研制了碳纤维混凝土复合拱桥体系。该系统可用于高65英尺以下的单跨桥梁设计,其结构由一系列碳纤维增强聚合物(CFRP)管组成,并在现场对这些管填充混凝土,然后在顶部铺上钢筋混凝土形成桥面。整个操作过程类似充气筏,而且CFRP管以折叠状态被运输到现场,因此整个施工过程也被称为“桥背桥”。据该材料中心的网站称,“折叠的CFRP管易于运输,可快速安装,不需要重型设备或大型工作人员来处理传统建筑材料的重量。”除了轻便之外,CFRP管还可用作混凝土模板,因此无需额外的材料。它们还具有无腐蚀性的混凝土增强功能,与易生锈的钢材相比具有明显的优势。 由于这些好处,该系统迄今已用于建造23座桥梁。

Despite the relatively high cost of carbon fiber, architects and engineers have started using it to construct buildings and infrastructural projects. For example, researchers at the University of Stuttgart’s Institute for Computational Design and Construction (ICD) and the Institute for Building Structures and Structural Design (ITKE) utilized carbon fiber as a prominent construction material in their latest work: the 2019 BUGA Fiber Pavilion at Bundesgartenschau Heilbronn in Germany, a dome made of glass-and carbon-fiber ribs clad in a transparent ETFE membrane. The team programmed a robot to deliver more than 492,000 feet of fibrous filaments in a spatial arrangement whereby fiber type and density could be varied based on structural loads. Designed to mimic biological systems, the carbon fibers surround the transparent glass fibers to form bundled structure members resembling flexed muscle tissues. According to the team, a single fibrous component can support “around 25 tons or the weight of more than 15 cars.” The dome, which has a free span of around 75 feet and shelters a floor area of 4,305 square feet, is composed of 60 of these components, each of which weighs only 16.8 pounds per square meter.

Although the ICD/ITKE work assumes the form of bespoke demonstrations, another research team has been deploying carbon fiber broadly in public infrastructure. The University of Maine’s Advanced Structures and Composites Center has developed a composite arch bridge system made of carbon fiber–reinforced concrete. Designed for single-span bridges up to 65 feet, the system consists of a series of carbon fiber reinforced polymer (CFRP) tubes that are filled with concrete on-site and then topped with steel-reinforced concrete decking. Similar to inflatable rafts, the CFRP tubes are transported to the site in a compact, folded state—hence the nickname “Bridge-in-a-Backpack.” According to the center’s website, “The arches are easily transportable, rapidly deployable, and do not require the heavy equipment or large crews needed to handle the weight of traditional construction materials.” In addition to their lightness, the CFRP tubes serve as the concrete formwork, thus eliminating the need for additional materials. They also function as noncorrosive concrete reinforcing, a clear advantage over rust-prone steel. Based on these many benefits, the system has been used to build 23 bridges to date.

Image: Advanced Structures & Composites Center at the University of Maine

这些例子都说明了重量对于碳纤维在建筑表达中的优势。但是,当一个建设项目还需要考虑可持续性时,此类轻质材料的表现又会如何呢?

在《工业周刊》2019年12月的一篇文章中,田纳西州诺克斯维尔高级复合材料制造创新研究所(Institute for Advanced Composites Manufacturing Innovation)扩大研究机构的负责人Ray Boeman解释说:“碳纤维具有最佳的轻量化潜力,但制造它需要耗费大量能源。”根据美国能源部(U.S. Department of Energy)和Lawrence Berkeley国家实验室(Lawrence Berkeley National Laboratory)进行的一项研究表明,典型的CFRP复合材料平均每次消耗800兆焦耳/千克(MJ / kg)的能量,而目前美国产量中的典型能量强度为1,134 MJ / kg。相比之下,钢铁需要50 MJ/kg,因此各自的节约比例为1:16和1:22。

此外,每生产一吨碳纤维,就会排放20吨二氧化碳。碳纤维也与化石燃料密切相关,因为最常见的原料是聚丙烯腈,这是石油化学工业生产的前体材料。通常用于制备CFRP的化学活化树脂或聚合物也是石油衍生的。《卫报》2017年的一篇题为《碳纤维:秘密的神奇材料》的文章揭示了碳纤维的生产影响及其回收所带来的困难。

These examples demonstrate how lightness—among other material attributes—gives carbon fiber an advantage in construction. But how does this lightness perform when a project also calls for enhanced sustainability?

In a December 2019 Industry Week article, Ray Boeman, director of the Scale-Up Research Facility at the Institute for Advanced Composites Manufacturing Innovation in Knoxville, Tenn., explains, “Carbon fiber has the best potential for lightweighting, but takes a lot of energy.” According to a study conducted by the U.S. Department of Energy and Lawrence Berkeley National Laboratory, a typical CFRP composite requires 800 megajoules per kilogram (MJ/kg) of primary energy, on average, with the current typical energy intensity in U.S. production of 1,134 MJ/kg. By comparison, steel requires 50 MJ/kg, resulting in respective savings ratios of 1:16 and 1:22.

Furthermore, for every ton of carbon fiber produced, 20 tons of carbon dioxide are emitted. Carbon fiber is also closely tied to fossil fuels, as the most common feedstock is polyacrylonitrile, a precursor material produced by the petrochemical industry. The chemically activated resins or polymers typically used to make CFRP are also petroleum-derived. The 2017 article in The Guardian entitled “Carbon Fiber: the Wonder Material with a Dirty Secret” reveals the production impacts as well as recycling difficulties of carbon fiber.

然而,对于特定的应用来说,碳纤维可促进碳足迹减少。据日本Toray工业公司称,这种材料可以显著降低交通运输工业的能源消耗:“当一辆汽车的车身结构因使用碳纤维而减轻30%时,那么每采用1吨碳纤维,就可以在10年的生命周期中减少50吨二氧化碳;另一方面,当使用碳纤维使飞机机身结构减轻20%时,同样的条件下将减少1400吨二氧化碳。”

那么,碳纤维对于静止不动的建筑物而言,是否也具有同样的环保效应呢?诚然,材料的重量和体积的减小,可以对建筑物生命周期的大多数阶段产生积极的影响,因为运输、安装和最终拆卸所需的燃料和重型机械更少。然而,对于建筑节能来说,尽管碳纤维对过热和环境退化的抵抗力可以延长建筑的使用寿命并减少维护,但其可操作性是一个更难论证的论点。

For specific applications, however, carbon fiber shines in the trade-off between operational and embodied footprint. According to the Japanese manufacturer Toray Industries, the material can lead to significant reductions in the energy requirements of transportation: “When the body structure of a car is made 30 percent lighter using carbon fiber, 50 tons of carbon dioxide will be reduced per 1 ton of carbon fiber over a life cycle of 10 years; when the fuselage structure of aircraft is made 20 percent lighter using carbon fiber, on the other hand, 1,400 tons of carbon dioxide will be reduced under the same condition.”

So does the material make environmental sense for immobile buildings? Material weight and volume reductions can deliver positive impacts in most stages of a building’s life cycle because less fuel and heavy machinery are required for transportation, installation, and eventual disassembly. The operational case for carbon fiber is a more difficult argument to make for buildings regarding energy savings, however—although the material’s resistance to excessive heat and environmental degradation can extend building life spans and reduce maintenance.

为了对是否在建筑中使用碳纤维做出明智的决定,设计团队必须对建筑预期寿命内的具体影响和操作影响进行全面评估。当然,没有详细说明的另一个重要考虑因素是成本。

从环境的角度来说,随着生物原料的增加使用、更高效的制造工艺和不断提高的回收率,这种材料的性能应该会得到改善。随着碳纤维在生态上越来越有利,Fuller用超轻建筑取代笨重建筑的梦想可能离现实更近了。

To make an informed decision about whether to use carbon fiber in architecture, a design team must conduct a comprehensive assessment of the embodied and operational impacts over the anticipated lifetime of a building. Another critical consideration that I don't detail here is, of course, cost.

Environmentally speaking, the material’s performance should improve with the increased use of bio-based feedstocks, more efficient manufacturing processes, and growing recycling rates. As carbon fiber continues to become more ecologically advantageous, Fuller’s dream of replacing ponderous buildings with ultralight architecture may move closer to reality.

|

|