建筑设计: Gramazio & Kohler, Bearth & Deplazes Architekten

地点:瑞士

总建筑师:托拜厄斯

项目年份:2006

摄影师:拉尔夫•费厄 贝阿斯&迪普拉彻斯建筑事务所Deplazes Architekten 09AUG 2012

Filed under: Featured ,Institutional Architecture ,Selected , Bearth & Deplazes Architekten, Fläsch,Gramazio & Kohler, Switzerland

甘特拜恩酒厂/格莱梅兹&科勒,贝阿斯&迪普拉彻斯建筑事务所

Architects: Gramazio & Kohler, Bearth & Deplazes Architekten

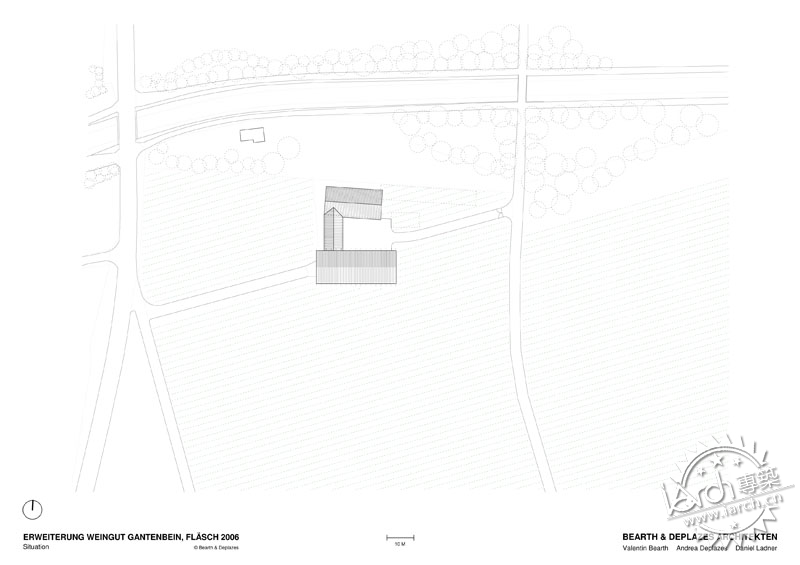

Location: Fläsch, Switzerland

Architect In Charge: Tobias Bonwetsch

Project Year: 2006

Photographs: Ralph Feiner, Courtesy of Gramazio & Kohler特许授权

特别鸣谢 翻译一组 9号 王一宁 提供的翻译,译稿版权归译者所有,转载请注明出处。

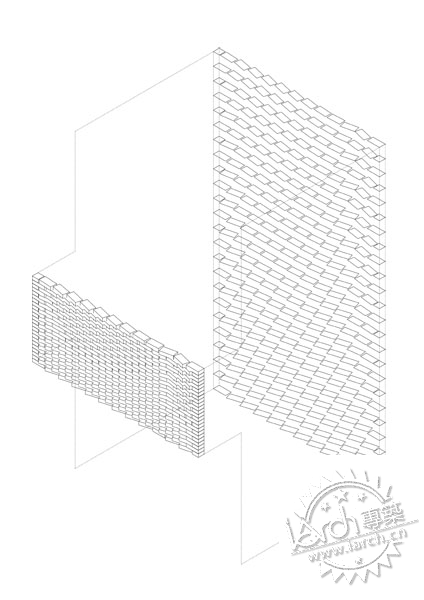

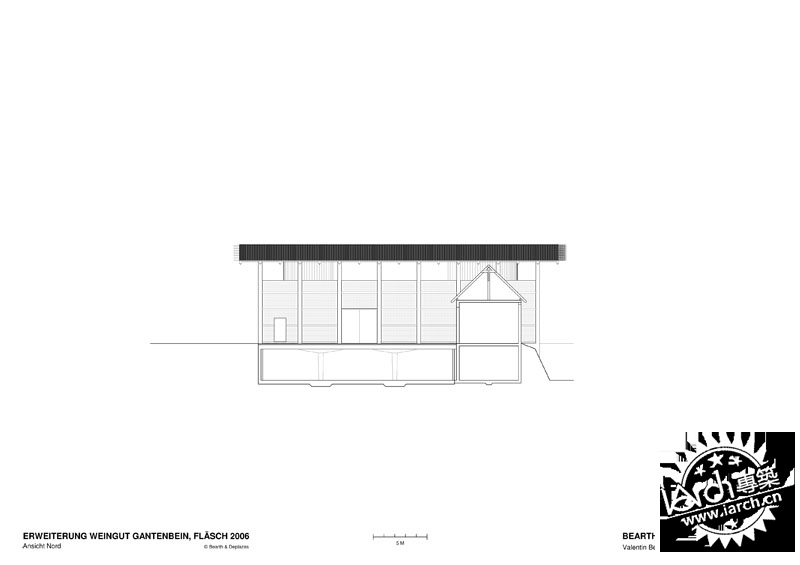

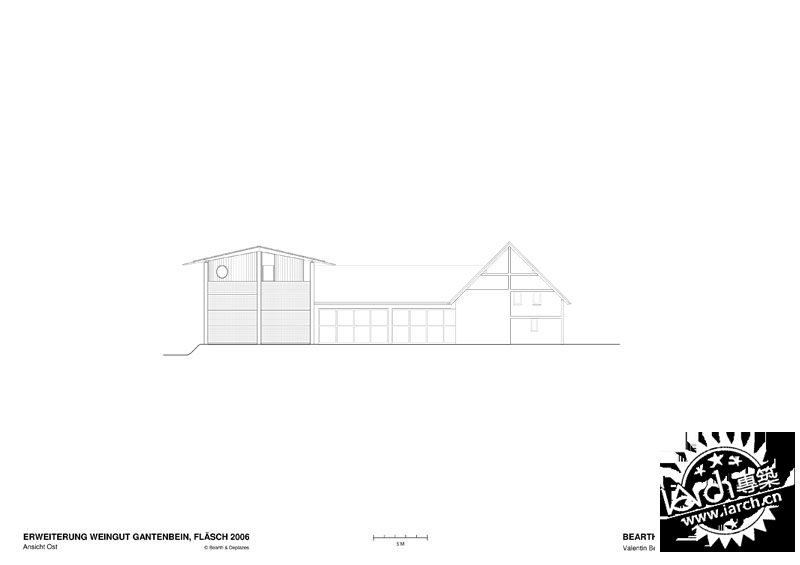

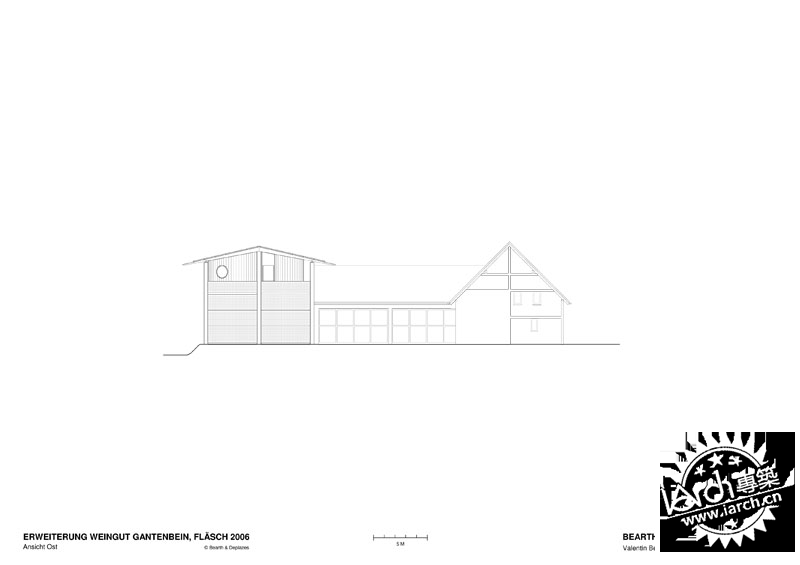

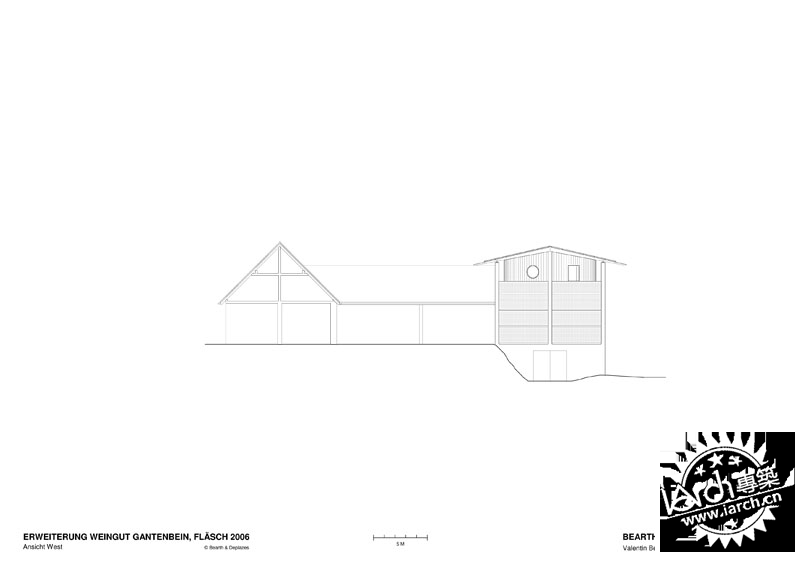

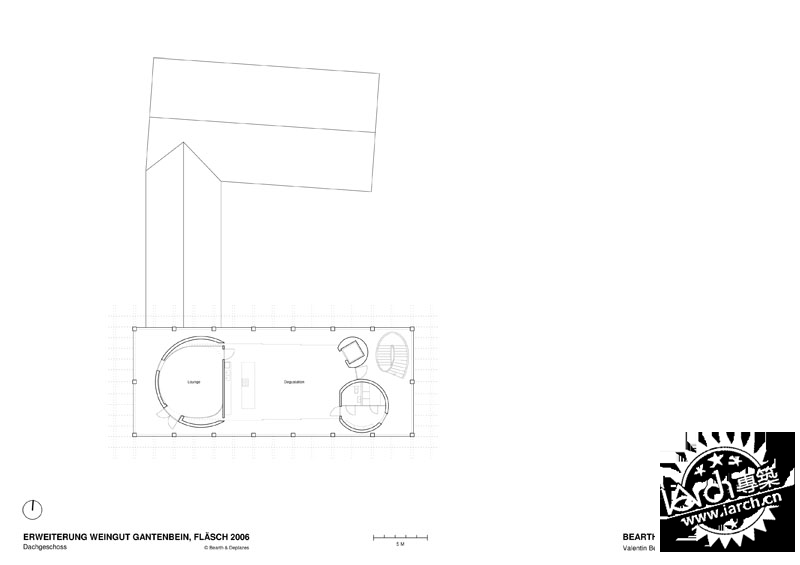

The project was realised as an extension of a small but remarkably successful vineyard. The wine producers wanted a new service building, consisting of a large fermentation room for processing grapes, a cellar dug into the ground for storing the wine barrels, and a roof terrace for wine tastings and receptions. Bearth & Deplazes Architects designed the project, and it was already under construction when they invited us to design its façade.

这个项目是为一个小规模却非常成功的葡萄园而建。葡萄酒生产商想要一座新的服务性大楼,包括一间处理葡萄的大发酵室,一个储存葡萄酒桶的地下酒窖和一个开品酒会和招待会的屋顶露台。 Bearth & Deplazes Architects设计了这个项目,当他们邀请我们来参与设计外观时已经在建设当中了。

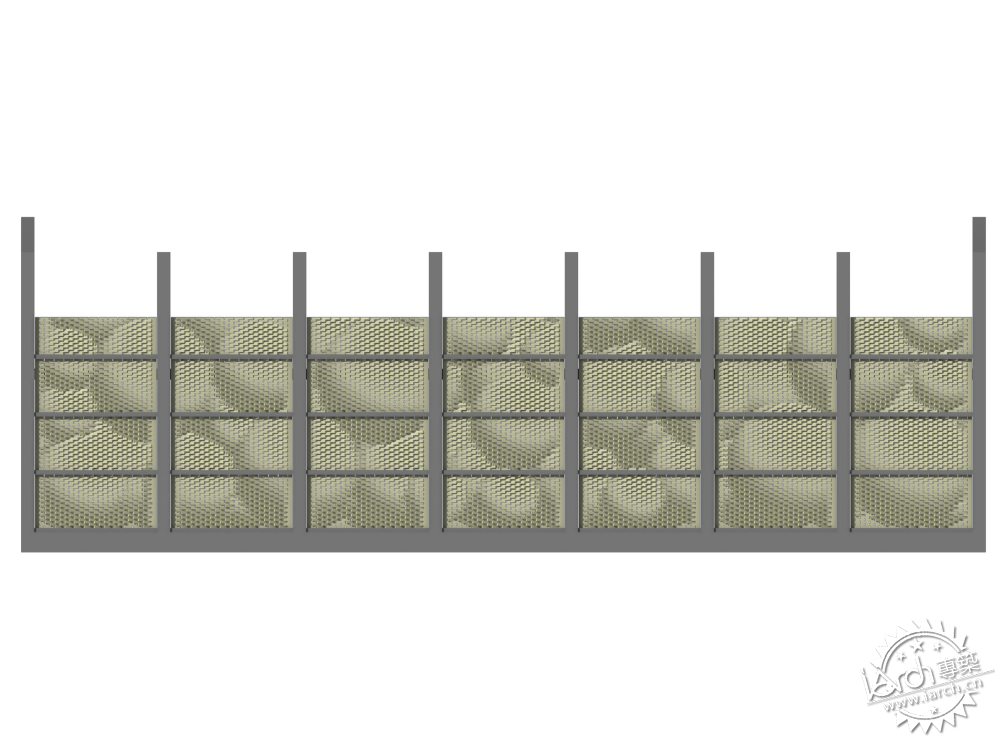

The initial design proposed a simple concrete skeleton filled with bricks: The masonry acts as a temperature buffer, as well filtering the sunlight for the fermentation room behind it. The bricks are offset so that daylight penetrates the hall through the gaps between the bricks. Direct sunlight, which would have a detrimental effect on the fermentation, is however excluded. Polycarbonate panels are mounted inside to protect against wind. On the upper floor, the bricks form the balustrade of the roof terrace.

最初的设计提出采用简单的砖混结构:砌石作为温度缓冲,同时为身后的发酵室过滤掉阳光。作为弥补,日光从砖缝透入大厅。而直射阳光由于对发酵不利则被隔除。为了防风,竖起了聚碳酸酯板。在顶层,砖又组成了屋顶平台的栏杆。

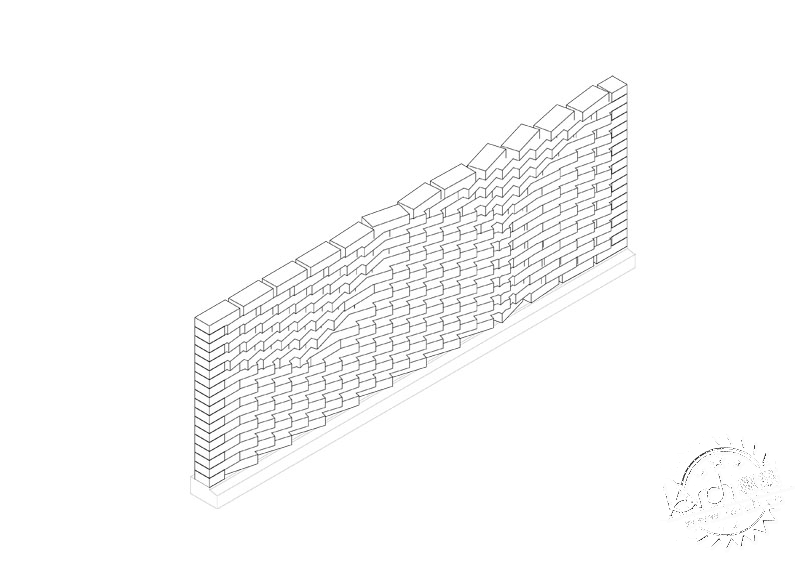

The robotic production method that we developed at the ETH enabled us to lay each one of the 20,000 bricks precisely according to programmed parameters—at the desired angle and at the exact prescribed intervals. This allowed us to design and construct each wall to possess the desired light and air permeability, while creating a pattern that covers the entire building façades. According to the angle at which they are set, the individual bricks each reflect light differently and thus take on different degrees of lightness. Similarly to pixels on a computer screen they add up to a distinctive image and thus communicate the identity of the vineyard. In contrast to a two-dimensional screen, however, there is a dramatic play between plasticity, depth and colour, dependent on the viewer’s position and the angle of the sun.

我们在联邦理工大学发展出的自动化生产方式使得我们能够将20000块砖精确地安放,根据编程参数将它们放在理想的角度和指定的空隙。这就要求我们将每道墙设计建设得具有理想的日照和空气渗透性,同时创造出一种覆盖整个建筑外立面的图案。安放的角度不同,每块砖都会反射出不同的光,因此具有不同的明亮度。与电脑屏幕上的像素相似,一起组成一个特殊的图像,传达出葡萄园的个性。然而与二维屏幕相反,在可塑性、深度和颜色上有着引人注目的表现,取决于观察者的位置和太阳的角度。

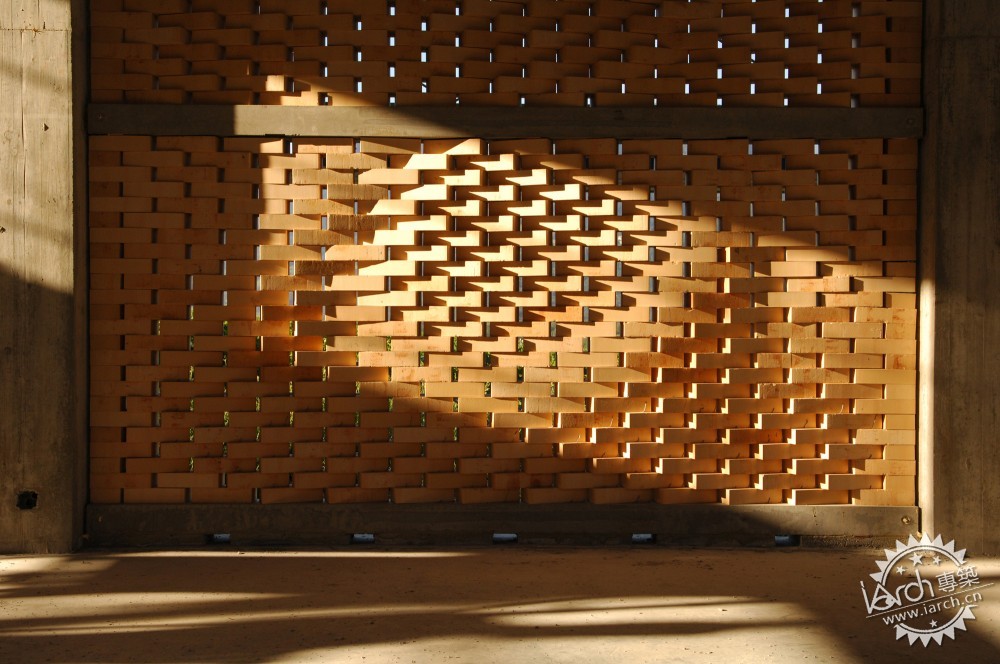

The masonry of the vineyard’s façade looks like an enormous basket filled with grapes. At closer view – in contrast to its pictorial effect at a distance – the sensual, textile softness of the walls dissolves into the materiality of the stonework. The observer is surprised that the soft, round forms are actually composed of individual, hard bricks. The façade appears as a solidified dynamic form, in whose three-dimensional depth the viewer’s eye is invited to wander. In the interior, the daylight that penetrates creates a mild, yet luminous atmosphere. Looking towards the light, the design becomes manifest in its modulation through the open gaps. It is superimposed on the image of the landscape that glimmers through at different levels of definition according to the perceived contrast.

葡萄园立面上的砖块看起来就像一个装满葡萄的大篮子。与远处的形象化效果相反,近看时墙体纺织品般的柔软感融化为砖石的实质感。观察者会惊讶地发现柔软、完整的形态实际是由独立、坚硬的砖构成的。立面形状是凝固而能动的,观察者的目光将被三维的深度所吸引而入内一游。在室内,透入的日光营造了温和而明快的氛围。朝光源看去,设计在露出的缝隙中变得更加明显,叠加在地形形象之上,在对比中随轮廓的层次而逐渐消隐。

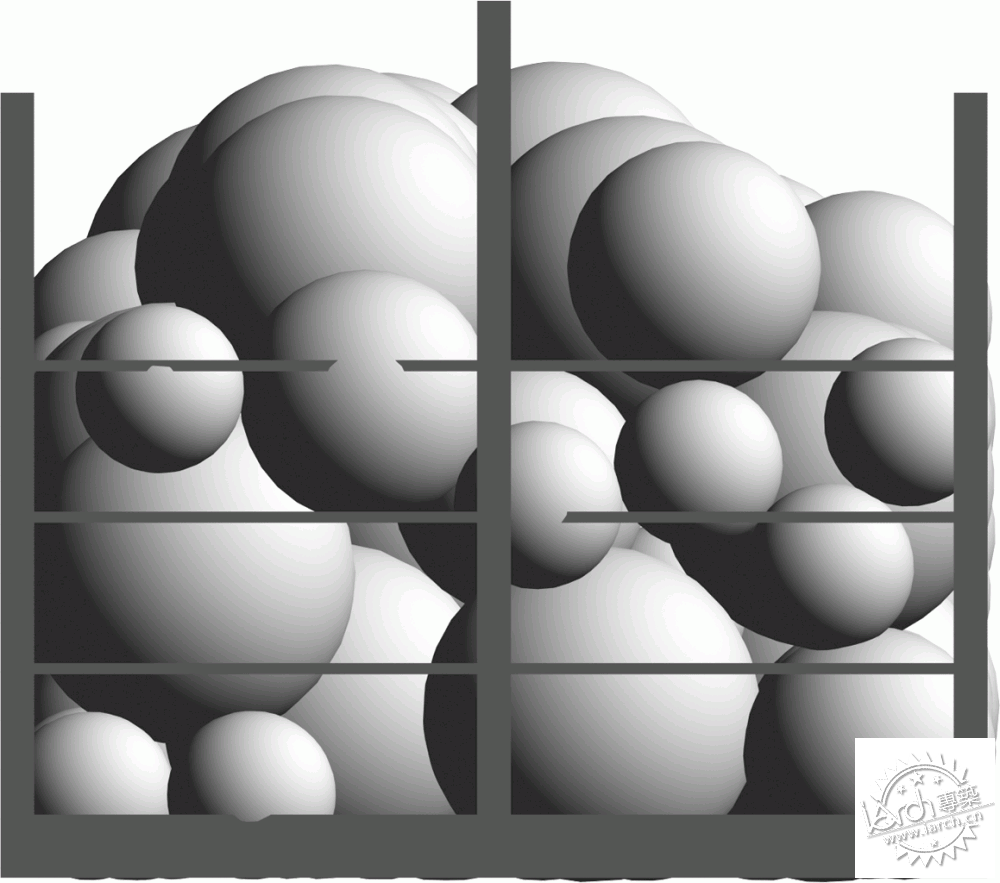

Falling Spheres To create the façade, we designed a generation process. We interpreted the concrete frame construction by Bearth & Deplazes as a basket and filled it with abstract, oversized grapes of varying diameters. We digitally simulated gravity to make the grapes fall into this virtual basket, until they were closely packed. Then we viewed the result from all four sides and transferred the digital image data to the rotation of the individual bricks. On the built façades, the visitor discerns gigantic, synthetic grapes, which were virtually inside the building as we developed our design. 掉落的球体 为了营造立面,我们设计了一个完善方案的进程。我们将贝阿斯&迪普莱彻斯的混凝土框架结构看成一个篮子,在其中装满了直径不同的抽象的大型葡萄。我们精确地模拟了万有引力使得葡萄落入虚拟的篮子中,直到它们紧密地安插起来。然后我们从四面考察结果,将数字图像的数据转换为单独的砖块。在建好的立面上,来客可以分辨出巨大的合成葡萄,实际在我们发展设计中是在建筑内部的。

However, the architectural implications of this brick façade are more elaborate and diverse than those of a two-dimensional image. To the human eye, able to detect even the finest difference in colour and lightness, the subtle deflection of the bricks create an appearance and plasticity that is constantly changing along with the movement of the observer and of the sun over the course of the day. 然而,砖墙立面的建筑蕴意要比二维图像更加精巧和多样化。对能够分辨差异最细微的色调和亮度的人眼来说,砖块微妙的反射使得外观随着一天中太阳和观察者位置变化而不断变化。

The joints between the bricks were left open to create transparency and allow daylight to trickle into the building. In order to make the pattern discernible from the interior we laid the bricks as close together as possible so that the gap at full deflection was nearly closed. This produced a maximum contrast between the open and the closed joints and allowed the light to model the interior walls poetically. 砖缝之间留白使得日光稀疏地漏进建筑物内。为了图案从室内也能分辨出来,我们将砖块尽可能近地摆放,这样完全偏移时缝隙就几乎是关闭的。在打开和关闭的接缝处就产生了一个最大的差值,让光线诗意地建造内墙。

Bricklaying

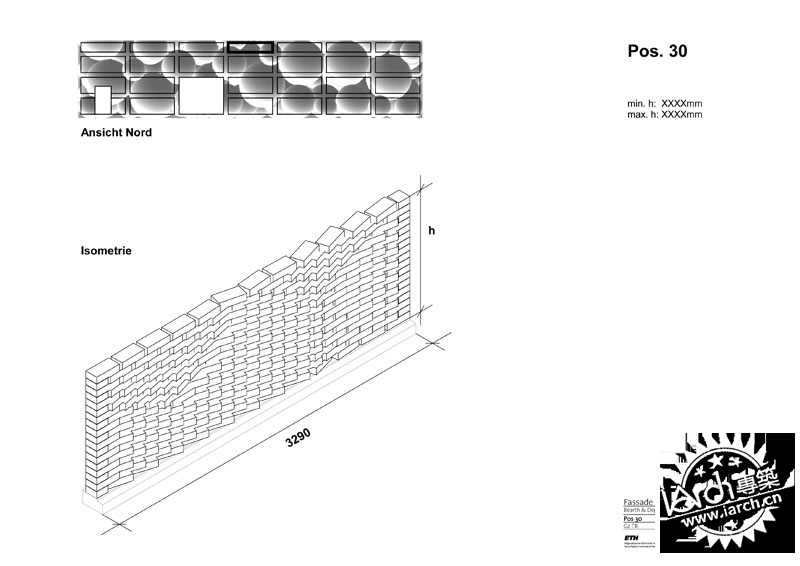

The wall elements were manufactured as a pilot project in our research facilities at the ETH Zurich, transported by lorry to the construction site, and installed using a crane. Because construction was already quite advanced, we had only three months before assembly on site. This made manufacturing the 72 façade elements a challenge both technologically and in terms of deadlines. As the robot could be driven directly by the design data, without our having to produce additional implementation drawings, we were able to work on the design of the façade up to the very last minute before starting production.

砖块摆放

我们在苏黎世联邦理工大学的研究机构将砖墙构成作为一个试点项目,货车运送到施工现场,用吊车安装。因为施工技术已经非常先进,我们在基地上集合之前只剩三个月。这使得安装72个立面部分成为了技术和时间的双重挑战。由于自动设备可以受设计数据直接操控,无需额外再制施工图,我们得以一直设计立面直到开始生产之前最后一刻。

To accelerate the manufacturing process for the 400 square metre façade, we had to develop an automated process for applying the two-component bonding agent. Because each brick has a different rotation, every single brick has a different and unique overlap with the brick below it, and the one below that. Together with the brick manufacturer’s engineer, we established a method in which four parallel bonding agent paths are applied, for each brick individually, at pre-defined intervals to the central axis of the wall element. Load tests performed on the first elements manufactured revealed that the bonding agent was so structurally effective that the reinforcements normally required for conventional prefabricated walls were unnecessary.

为了加速400平米立面建造进程,我们不得不研发一种适用于双组份黏合剂的自动化工序。因为每块砖都有一个不同的旋度,与上下相邻两块砖均有不同的交叠。同砖体生产厂家的工程师一起,我们建立了四条平行黏合剂路径的使用思想,每块单独的砖块距墙体组件中心轴特定的距离。第一个制造好的部件经过负重测试表明,黏合剂结构上是如此有效以至于不需要通常加固用的常规预制墙。

|

Children’s Library Discovery Center 儿童图书馆探索中心

Children’s Library Discovery Center 儿童图书馆探索中心